ARCHWEIGH BELT SCALES

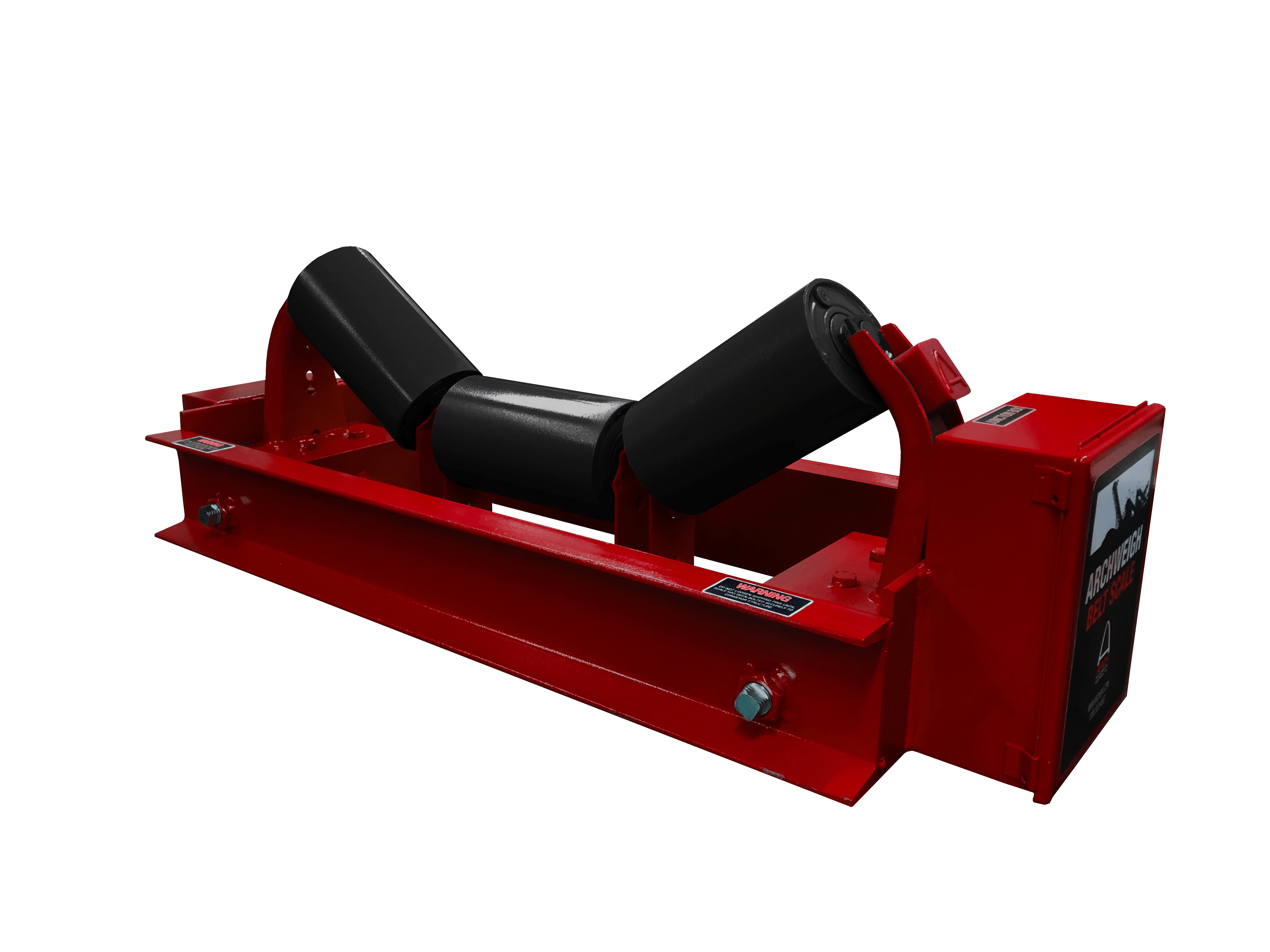

Archweigh SC Belt Scale

The Archweigh Dual SC offers a weight accuracy of 1% – 2% as it self-adjusts to the movement of the belt, thanks to Arch’s patented dual-ended load cells. This unique engineering compensates for outside forces on the belt by forcing converse reactions by the load cells; one is forced up while the other pushes down. (Constant recalibration is never necessary)

No assembly required, Bolt-in-Place Installation, Minimum Recalibration

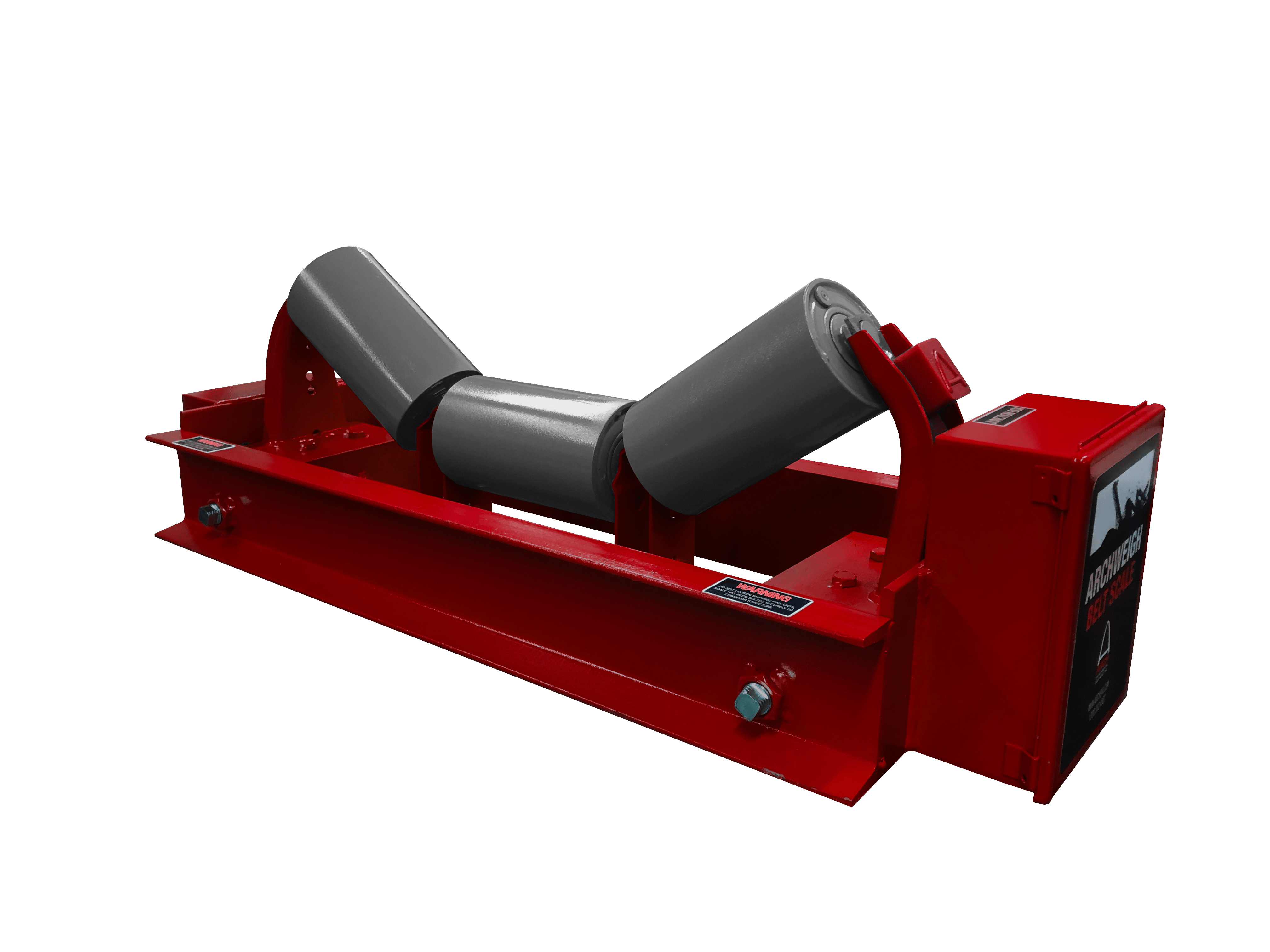

Archweigh HP Belt Scale

The Archweigh HP is the only belt scale that accounts for outside forces that affect every conveyor. Arch’s patented dual-ended load cells mount directly to the idler, and provide reliable, accurate data (up to +/- 1/2%) every day without recalibration. The dual load cells work opposite each other to neutralize the natural lateral and vertical movements of your conveyor belt. As a force pushes down one end, that same force naturally lifts the other; any movement is cancelled out.

No assembly required, Bolt-in-Place Installation, Minimum Recalibration

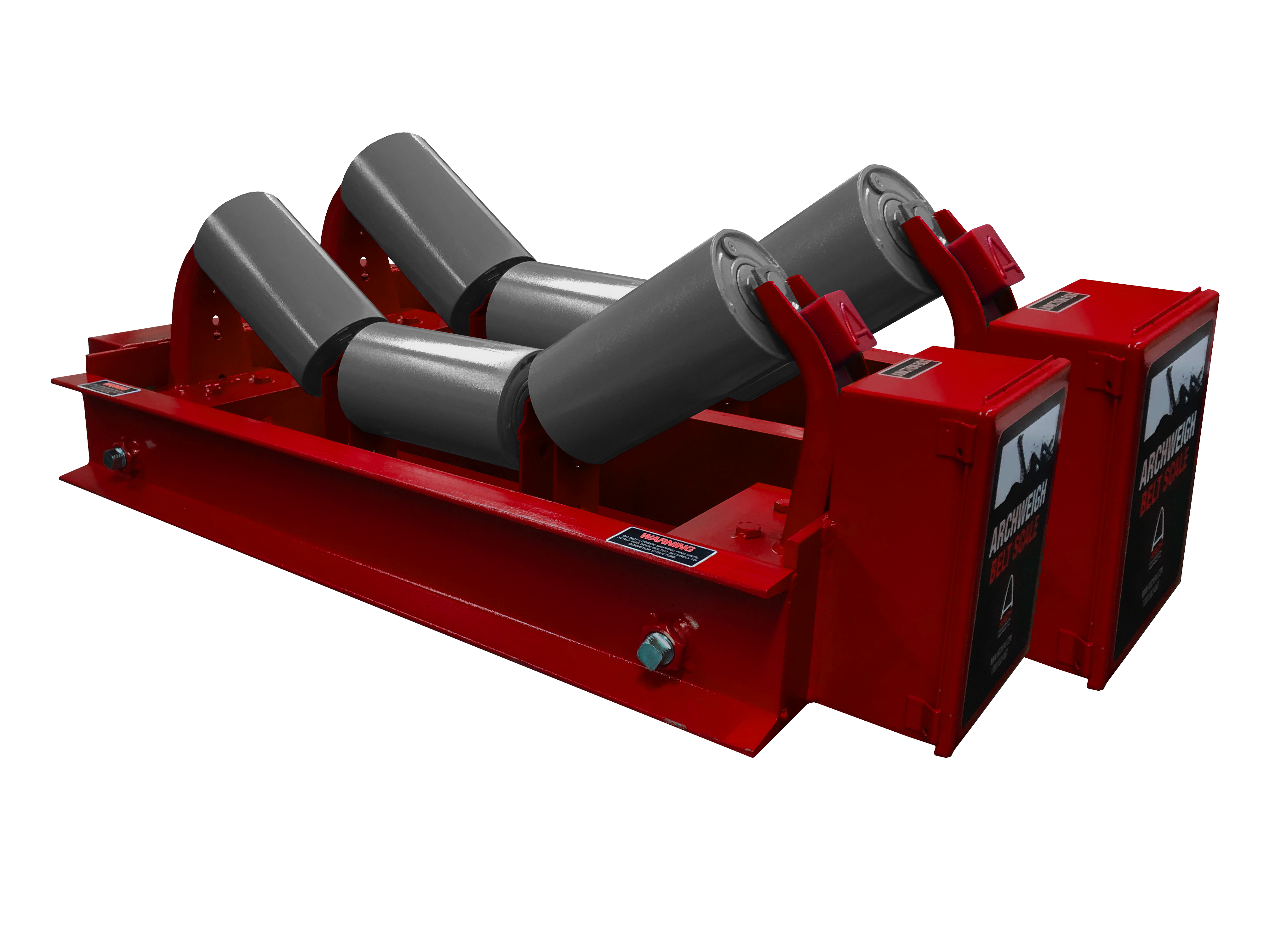

Archweigh Dual HP Belt Scale

The Archweigh Dual HP offers a weight accuracy of 1/4% as it self-adjusts to the movement of the belt, thanks to Arch’s patented dual-ended load cells. This unique engineering compensates for outside forces on the belt by forcing converse reactions by the load cells; one is forced up while the other pushes down. (Constant recalibration is never necessary)

No assembly required, Bolt-in-Place Installation, Minimum Recalibration

ARCHWEIGH SCALE INTEGRATORS

Manages Up To 6 Scales-Touchscreen Display-Unlimited Communication Options.

The Archweigh belt scales are uniquely designed mechanically and electrically. Arch’s patented load cell design eliminates problems associated with weighing material on a moving conveyor belt. With other scales, the force created by the movement of the belt over the scale carriage is factored as a component of the calibration weight or Belt-Tare. The assumption that mechanical components will not vary over time results in a lack of long term accuracy and repeatability. Therefore, the output value of the load cell is always only the weight of the material on the belt, nothing more and nothing less. With our scales, there are no parts to bolt together or kits to figure out. Let us prove to you that we provide better service, installation, and belt scales. Arch installation services are available to any of our customers or we’ll train your staff to properly install, set up, calibrate and maintain your equipment.

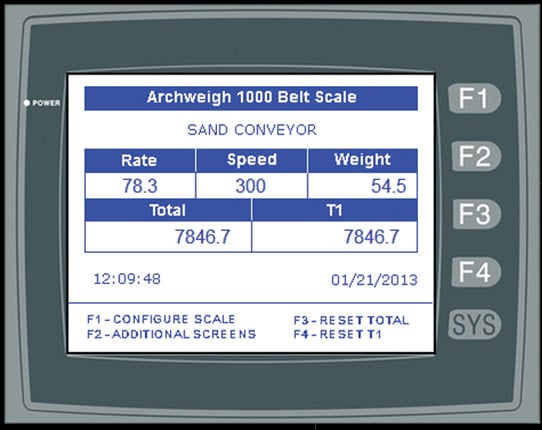

Archweigh 1000 Scale Integrator

The Archweigh Integrator utilizes a unique Analog-to-Digital conversion process which allows for the use of an industry standard programmable logic controller (PLC) as a control processor. The exclusive converter internally performs thousands of weight and speed calculations per minute and transmits that high accuracy value to the PLC. The processor then uses those numbers to perform basic rate, weight, and totalizer calculations.

Single-Scale Integrator-Touchscreen Display-Unlimited Communication Options

Archweigh 2000 Scale Integrator

Built with the same rock-solid, time-tested software and analog-to-digital conversion as the Archweigh 1000, the Archweigh 2000 is built for multiple scales carriages. A 6″ touch screen display makes set-up and calibration easy to do anywhere. A steel enclosure makes the ArchWeigh 2000 as tough as the environment it works in.

Terms & Conditions · FAQs · © Copyright 2021 Arch Environmental Equipment, Inc., All rights reserved.