BELT & PERSONNEL PROTECTION

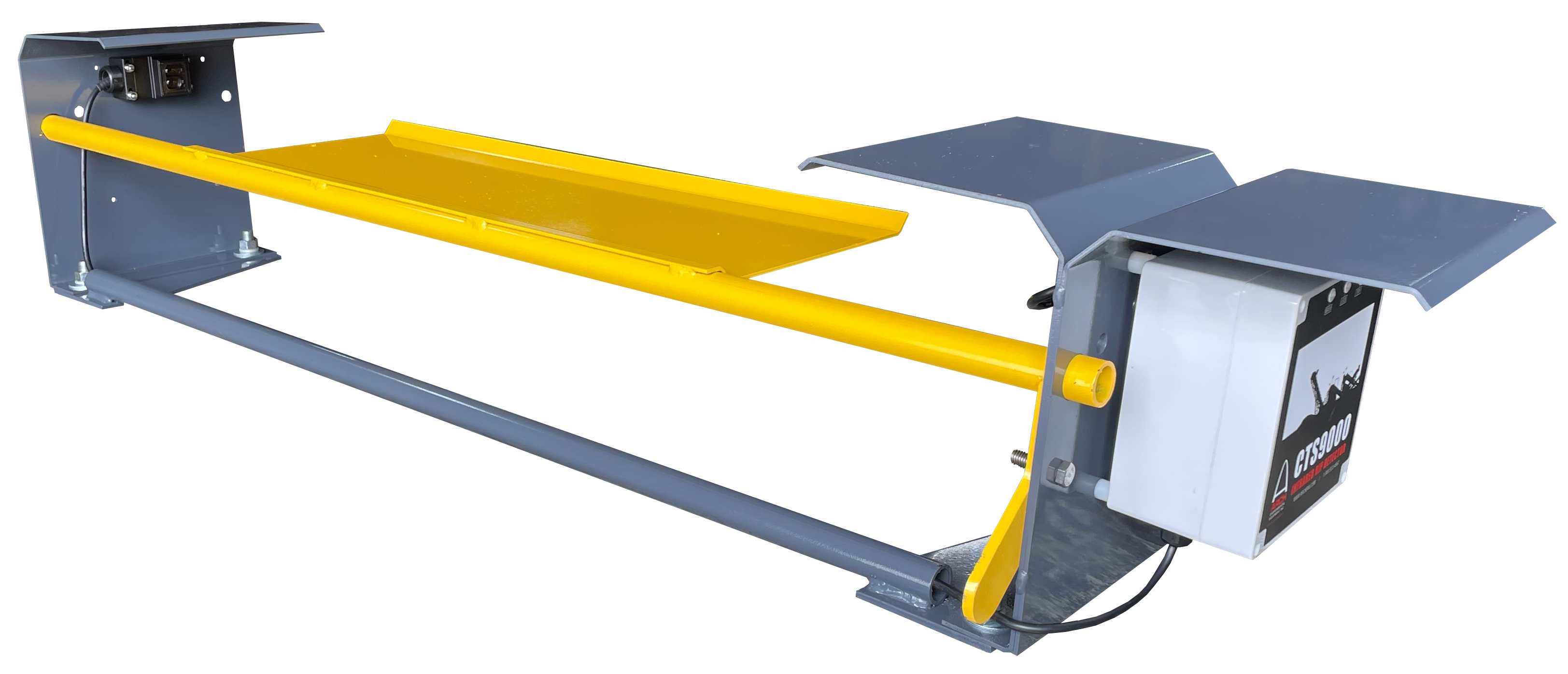

CTS 9000 Infrared Rip Detector

The CTS 9000 IRD is equipped with a push-button that starts a wash cycle without stopping the conveyor. The wash cycle will allow the operator five minutes to clear the lens and the unit will return online automatically. The total unit consists of 3 IP 66 enclosures mounted on a metal bracket facing each other with the sensing beams, an electronic control unit which is mounted on the bracket facing out, and a special metal tray to catch the falling material.

Auto-Wash Mechanism, For Belts 24” to 96”, Minimum Recalibration, High-Impact Housing

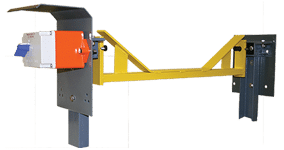

CTS 700 BTR Rip & Tear Detector

The CTS 700 BTR’s two profiled arms connect to a rotary switch equipped with a mechanical delay to prevent trips from incidental contact.

(Once activated, the switch must be manually reset)

For Belts 24” to 96”, Detects Side Wing Tears and Center Rips, High-Impact Housing

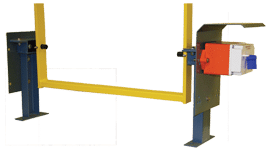

CTS 700 BL Belt Misalignment Detector

Arch’s CTS 700 BL utilizes a mechanical delay to prevent trips from incidental misalignment. The switch features two upright arms connected to a rotary switch that will shut down a conveyor before damage is done.

(Once activated, the switch must be manually reset)

For Belts 24” to 96”, Bolt-in-Place Installation, Detects Misalignment in Both Directions

CTS 700 RBL Return Belt Misalignment Detector

The CTS 700 RBL uses two downcast arms to detect misalignment of a return belt. Should the belt run off to the right or to the left to the extent that it can cause damage to the belt or the conveyor structure, it will come into contact with one of the downcast arms. These arms are connected to an electrical switch via a glass-reinforced polycarbonate made coupling mechanism.

For Belts 24” to 96”, Bolt-in-Place Installation, Heavy Duty Housing

CTS 600 BCD Blocked Chute Detector

The CTS 600 BCD blocked chute detector is a tilt-type switch, which is mounted inside the chute to monitor any blockage in the material conveyed. Should material start to build up due to a blockage, it will lift the sensing rod, tilting the switch; any tilt to the switch above 15 degrees will cause one of the steel-encapsulated switches to open. This unit provides a relay interface between a tilt-type probe and the conveyor control system.

Polyurethane Construction, Encapsulated Probe, Adjustable Timer, Corrosion Resistant

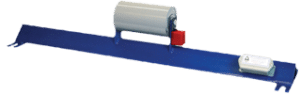

CTS 700 OSU Belt Off Speed Monitor

The CTS 700 OSU uses a roller mounted underneath the troughing belt to detect belt movement. A pulse sensor is mounted on the roller structure and monitors the pulses in magnetic proximity mode.

Easy Setup, Zero Speed Monitor Also Available

CTS 900 AVA Audio/Visual Pre-Start Alarm

The CTS 900 AVA alarm unit is housed in a high impact UV stabilized polycarbonate enclosure rated to IP 65 degrees of protection. The unit consists of: 1 alarm buzzer rated 105 dB and a flashing strobe light.

Audio AND Visual Alarm, Heavy Duty Housing, Corrosion Proof

CTS 100 Standard Rotary Switch

The CTS 100 uses an electrical rotary switch, allowing personnel to trip it manually. The electrical switch is a self-wiping rotary switch (not a micro-switch), and consists of two normally open and two normally closed contacts. Once the switch has been tripped, the Orange colored flag is in the “Up” position to alert maintenance personnel. It must then be manually reset in order to restart the conveyor.

Non-Hazardous Environments Only, Self-Wiping Rotary Switch, Lockable Switch

CTS 200L Standard W/Trip Light

The CTS 200L uses an electrical rotary switch, allowing personnel to trip it manually. The electrical switch is a self-wiping rotary switch (not a micro switch), and consists of two normally open and two normally closed contacts. Once tripped, the Blue colored flag is in the “Up” position the light is illuminated (making it visible to maintenance personnel). It must then be manually reset in order to restart the conveyor.

Non-Hazardous Environments Only, Self-Wiping Rotary Switch, Trip Indication, Lockable Switch

CTS 300PSW Switch W/Pre-Start Alarm

The CTS 300 PSW is a self-wiping rotary switch (not a micro-switch), and consists of two normally open and two normally closed contacts. Once the switch has been tripped, the Blue colored flag is in the “Up” position. The CTS 300 PSW also emits an “Audible” alarm sound before “Start Up” of the conveyor to warn maintenance personnel that the conveyor is about to start.

(This switch should only be used in conjunction with an Arch “CMS Conveyor Monitoring System” and not as a stand-alone switch. Once tripped it must be manually reset to restart the conveyor)

Hazardous/Non-Hazardous Environments, Audio/Visual Pre-Start Alarms, Trip Indication LEDs, Lockable Switch

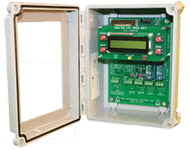

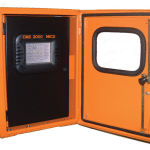

CMS 3000-HECU Head End Control Unit

The CTS 3000 is an intelligent, programmable control unit with internal fault diagnostics. The Head End Control Unit (HECU) controls, monitors, and supervises all safety and belt protection devices. Each fault condition is identified and displayed by name/type on the Touch Screen. The HECU provides maintenance personnel with the information necessary to locate problems quickly, minimizing conveyor downtime.

EMT 50 Metal Detector

The EMT 50 has a 5 percent sensitivity level and can be tuned to ignore conductive or magnetic ores, such as magnetite or pyrite (even if they’re carried by high-tension steel cord belts with rip detection loops). The EMT 50 will still detect small pieces of tramp metal. Its lightweight construction allows for easy assembly and installation, even as a flat-pack, under-belt style.

(Available for nearly any belt width)

EMT 100 Metal Detector

Equipped with a 10 percent sensitivity level, the EMT 100 can detect both ferrous and non-ferrous metals. It can be used on belts containing metallic repair clips or splices with our optional clip detector. The aperture can be adjusted up to 23.5” to accommodate burden heights up to 19.5.” The lightweight, flexible design also allows the detector aperture to be moved in the field.

(Available for belt widths up to 48)

Terms & Conditions · FAQs · © Copyright 2021 Arch Environmental Equipment, Inc., All rights reserved.